RAMPA's "power packs" with ETA approval

Are uncompromising safety and permanently stable connections in timber constructions just as important to you as they are to us? Then it’s a very good fit: Because we rely on the development of test series that are recognised throughout Europe! So if you need guaranteed mechanical properties and calculated values, the use of our ETA-approved threaded inserts is a reliable connecting element.

What is ETA and where are ETA items typically used?

The European Technical Approval (ETA) is a recognised proof of the technical suitability of a non-harmonised construction product in the sense of the Construction Products Directive of the EU member states. ETA products are also popular in these areas:

- Wood construction

- Staircase construction

- Window construction

- Bridge construction

- Public construction

- Fall protection

- Railing attachments

- Balcony attachments

- Canopy attachments

- Awning attachments

Because all these application areas have at least one thing in common: Safety and a high holding retention power are capitalised here! And a high level of safety also includes stable connections with recognised construction approval.

Overview of the advantages of RAMPA's ETA-approved threaded inserts

+ Extract values immediately calculable through our RAMPA customer service

+ Guaranteed mechanical properties

+ Minimum edge distances (1.5 x diameter)

+ No static individual approval necessary

+ Works in hardwood, softwood and many wood-based materials

+ Extensive specifications for use and processing

We want to constantly improve for you and thereby maximise the benefit to you! Due to our extended ETA approval ETA-12/0481 dated 22.03.2021, we cover many additional application areas with our ETA-approved threaded inserts for wood , for example through reduced edge distances or shorter construction lengths. This opens up a whole new variety of possibilities for you! Whereas previously our ETA-approved products were only approved for softwoods, the extension means that in addition to softwoods (for example spruce and pine), hardwoods (for example oak and beech) and derived timber products (for example OSB, MDF, multiplex and chipboard) are also approved.

Download:

Please notice: We supply ETA-certified BL & SKL inserts directly from stock. If you need other insert types, please do not hesitate to contact us.

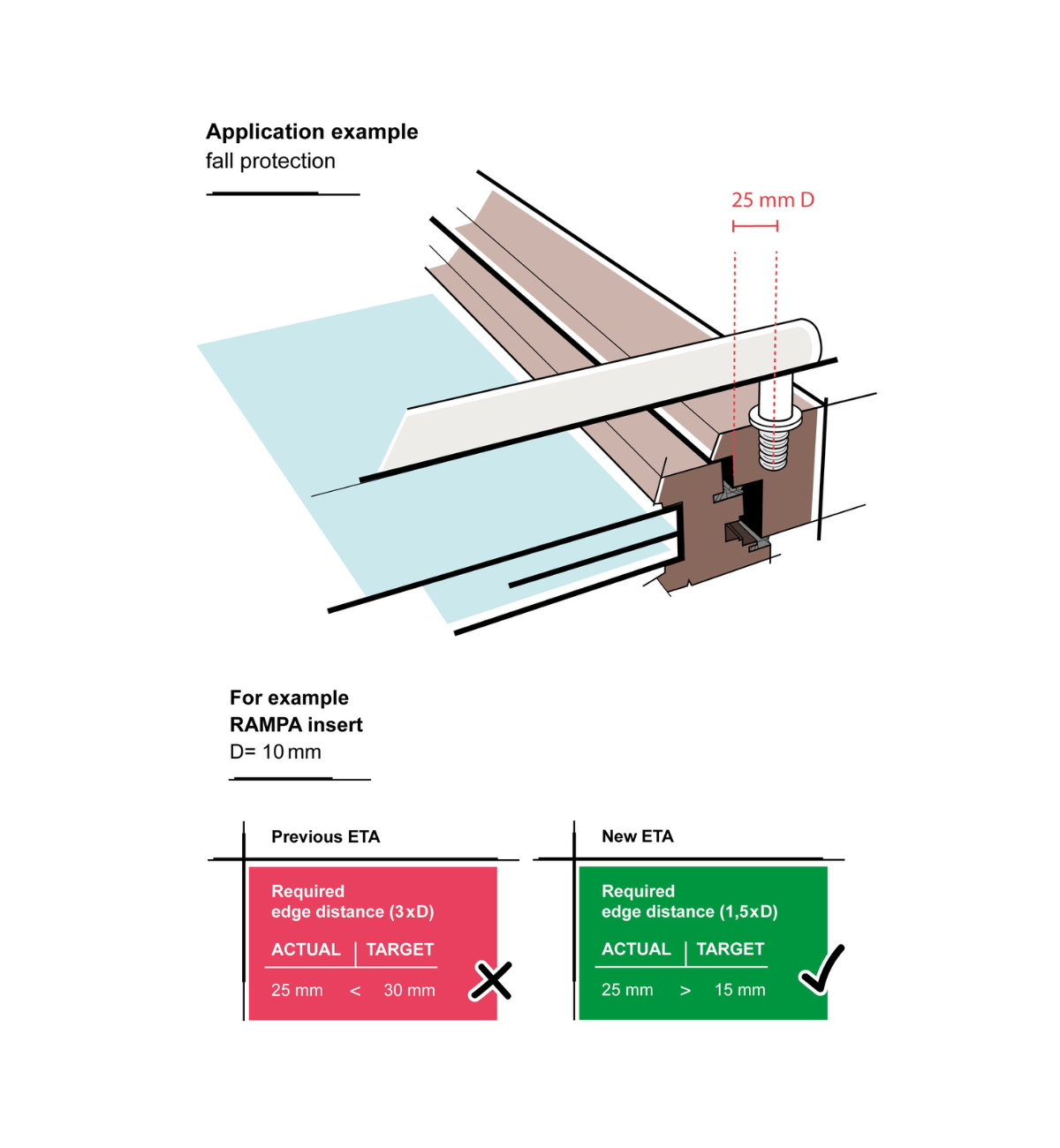

Advantages of reduced edge distances using the example of a fall protection system

Since we were able to reduce the required edge distance to 1.5 x diameter through product optimisation, it is possible to install French balconies or guardrails directly in the frame while maintaining a very high holding retention power. This saves a time-consuming assembly in the as well as a costly static individual acceptance!

The initial problem:

Due to the geometry of the frame, the users faced the challenge of small edge distances. This challenge could not be solved by the old ETA pertaining to RAMPA inserts type SKL and BL. The reason: The minimum distance

RAMPAs solution:

We are enthusiastic about the variety of possibilities and rely on strong connections! With optimized products, we were able to prove in numerous tests that all necessary static requirements can still be met with a reduced edge distance of 1.5 x diameter. This is confirmed and certified by ETA-12/0481.

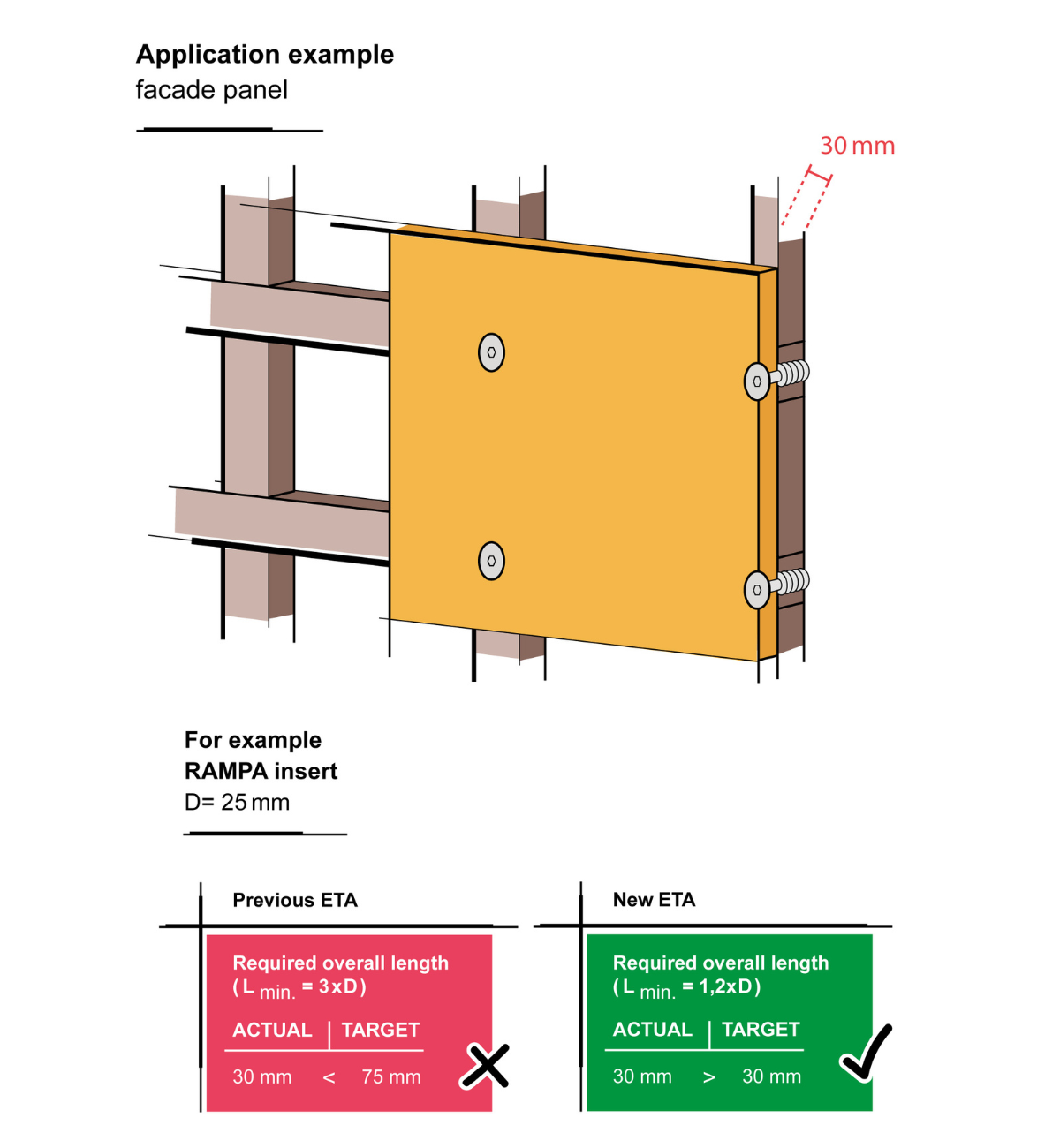

Advantages of the shorter construction lengths using the example of fastening/attachment of a facade panel

Product optimisations have also enabled us to reduce the required screw-in depth to 1.2 x diameter. This allows facade elements shorter length inserts to be installed while retaining high holding retention power.

The initial problem:

The specified counter-battening specifies a low screw-in depth of the inserts. This challenge could not be solved using the old ETA pertaining to RAMPA inserts type SKL and BL. The reason: The minimum screw-in depth of 3 x diameter could often not be implemented in reality.

RAMPAs solution:

We took up the challenge for you and achieved positive results! By optimising the products, we were able to prove in numerous tests that the corresponding screw-in depth can be reduced to 1.2 x diameter. All necessary static requirements can still be met. This is confirmed and certified by ETA-12/0481.