RAMPA inserts in metal applications - Good idea. Let’s make it!

Are you looking for the right RAMPA insert for your metal application? We are enthusiastic about the wide range of possibilities - also in the material metal. Starting in 1907 with threaded inserts for wood processing, we have continuously developed and expanded our portfolio to include plastics and metal.

Our aim is to develop all-round solutions in order to continously cover a wide range of materials or alloys. For example, the self-cutting RAMPA inserts are also among our strong all-round talents.

Whether metal alloy or plastic application: With our threaded inserts you can reduce the variation in threaded inserts. Additionally, you always generate a high retention holding power or best strengths in connection with the connecting elements .

Nevertheless, there are special cases that can’t be solved with a standard solution. This is where our many years of experience come into play once again. This allows us to always find or develop a solution for your application.

There are thousands of metal alloys and even more use cases or applications. Constantly varying requirements, such as strength, component weight and resistance to certain media, require specific consideration of the application.

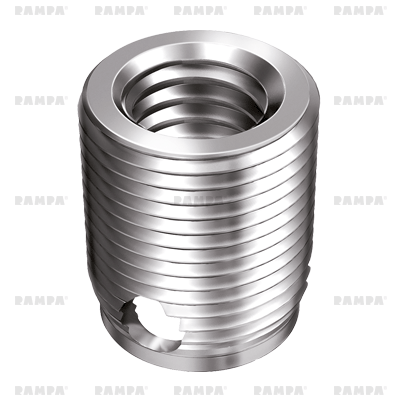

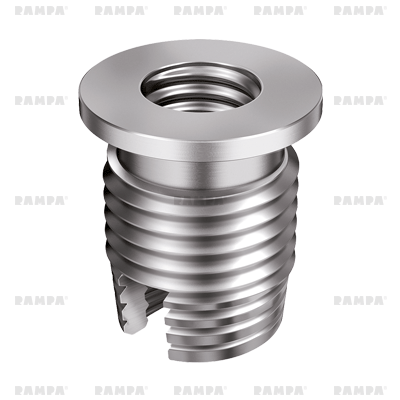

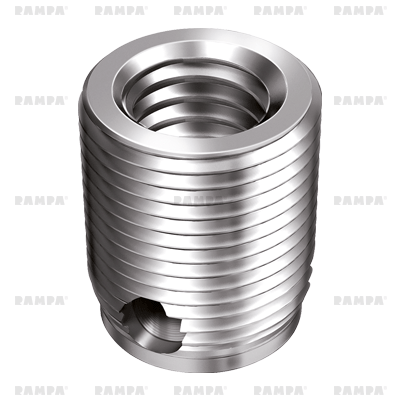

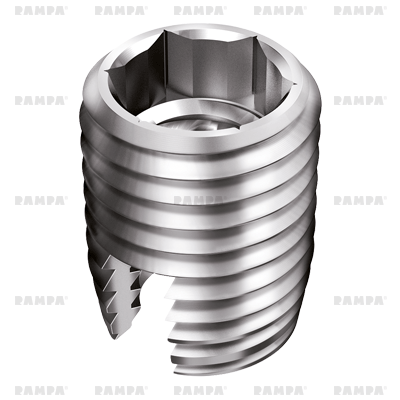

Our self-cutting threaded inserts are suitable for metal alloys up to a tensile strength of 300 N/mm2. They ensure that the required screw-in depth in e.g. EN AW-5083 (AlMg4.5Mn) can be reduced while maintaining the same strength, which in turn saves material.

Moreover, with our threaded inserts for metal processing, you get a connection that can be detached over and over again. Trouble with wear and tear? Rely on our threaded inserts for metal!

Torn threads due to incorrect application of the insert or screw or "wearing" of the thread during repeated disassembly are a thing of the past. Our screw-in inserts are very well suited for lightweight construction. Good idea. Let’s make it!

Advantages of using RAMPA inserts in metal applications at a glance:

- The external thread enables low-stress processing and ensures process

- Reliable and reproducible screw-in conditions.

- Our threaded inserts are self-cutting, so additional pre-cutting in the pilot hole is not necessary.

- Wide range of applications of our threaded inserts: In light metals such as aluminum, magnesium as well as bronze and other cast materials.

- Different designs of threaded inserts for metal available, including with collar or, for example, with chip spaces. This eliminates the need for additional cleaning of the screw-in area.

Fields of application of our RAMPA inserts in metal:

Whether general mechanical engineering, vehicle construction or shipbuilding - metals are used in a wide variety of forms and metal alloys . Our RAMPA inserts for metal as a link between base components and screws provide the required vibration-proof strength, especially in lightweight construction. In the following other areas, for example, threaded inserts from RAMPA can be found:

- Plant engineering

- Rail vehicle manufacturing

- Automotive engineering/Caravaning

- Aviation

- And many more!

Further details of the many applications of our RAMPA products in metal processing can be found in our inspiration area or in the reference projects section! You can purchase the preferred threaded inserts directly from our RAMPA-shop!

You work in a metalworking industry and have a special application for which you are still looking for a suitable threaded insert? No challenge is too great for us. Together we will find the best fit threaded insert for your project.

If there is nothing suitable in our wide range of standard products, we will work with you to develop custom solutions for your project. Feel free to call us for a consultation! Good idea. Let’s make it!