RAMPA's Reduction strategy

Goals and measures

We identified the areas where action was still needed and the specific measures to be taken to reduce our CO₂ emissions based on our carbon footprint. At RAMPA, we have adopted the following reduction targets based on the Science Based Targets initiative (Ambitious corporate climate action – Science Based Targets):

- By the year 2025 we will reach the maximum of 20 % of the value according to our balance sheet data from 2020 in the areas of scope 1 and 2.

- By the year 2030 we will reach the maximum of 10 % of the value according to our balance sheet data from 2020 in the areas of scope 1 and 2.

- Going forward, we will continue to offset the unavoidable emissions from scope 1 and 2 in a meaningful way in order to achieve sustainable climate neutrality* in these areas.

- Upstream and downstream activities from Scope 3: As part of our climate strategy, we are working in detail on the consideration and reduction of greenhouse gas emissions from upstream and downstream activities. Through our partner FORLIANCE, we are obtaining advice on this in the form of various emissions scenarios so that we can draw on reliable data for the future definition of reduction targets in Scope 3.

Overview of reductions to date in Scope 1 and 2

We have put our strategy into action:

- In 2021, within one year, we achieved a 45% reduction in CO₂ intensity. By switching our operations to green electricity from renewable sources, we managed to set our CO₂ emissions from scope 2 to zero, successfully reducing our environmental impact for scope 1 and 2.

- In the following year 2022, we were able to achieve a further 6% reduction in CO₂ intensity in Scope 1 and 2 due to our reduction strategy.

Further measures within the framework of our reduction strategy:

Our commitment to maximum-raw material recovery in the production process

For decades, we have ensured that in the production of threaded inserts or sockets for wood, metal or plastic constructions, the residual materials produced are not disposed of, but are used almost 100% for raw material recovery:

- Since 2009, we have been operating all cooling and lubrication processes only with high-quality oils, which we process and reuse in-house without residual waste.

- The chips produced during the production process are separated from the oil by centrifugal force and returned to the material cycle by recycling at our partner companies. On some sensitive machines, filter fleece is installed upstream to collect further chips. Only the filter fleece with the remaining chips cannot be reused and must therefore be disposed of. This small proportion of raw materials that cannot be recycled is approx. 0.1%.

Our Commitment to CO₂ compensated Parcel Deliveries

In logistics, sustainability is not only a focus of our internal processes: we strive to collaborate with partners who also take responsibility for sustainability in their operations.

Our Partners:

- With DHL Paket we ship nationally with reduced CO₂ emissions through the GoGreen Plus program. GoGreen Plus is a market leader in climate protection initiatives.

- FedEx has committed to achieving carbon neutrality by 2040. This goal includes transitioning to electric vehicles for first- and last-mile deliveries and adopting alternative fuels in air transportation.

- We chose DB SCHENKER based on sustainability criteria, which are transparently documented in their annual sustainability report and their ISO14001 (Environmental Management) certification.

- The Raben Group places a strong emphasis on sustainable logistics. As part of their 5-year action plan “Eco2way 2025,” Raben is actively working to reduce emissions. They have also received a silver rating from EcoVadis for their sustainability efforts.

- GLS follows the GLS KlimaProtect program, which aims to reduce, avoid, and offset CO₂ emissions. The company has been awarded a silver rating by EcoVadis for its sustainability efforts.

Our commitment to paperless work and less packaging waste

Thanks to the advancing digitalization of our processes and a comprehensive update of the enterprise resource planning system in 2020, we have succeeded in making our entrepreneurial activities largely paperless: From purchasing, through production and sales, to order picking, almost all processes are handled digitally. Hereby, RAMPA succeeded in facilitating the commercial employers to work from home due to Covid-19 within a very short time.

We are also against wasting resources when it comes to our packaging waste in incoming goods. Instead, we rely on recycling for greater sustainability: Incoming filling material – regardless of whether it is made of paper, cardboard or plastic – is not disposed of at our company but reused for outgoing goods shipments.

Our commitment to clean and minimal energy consumption

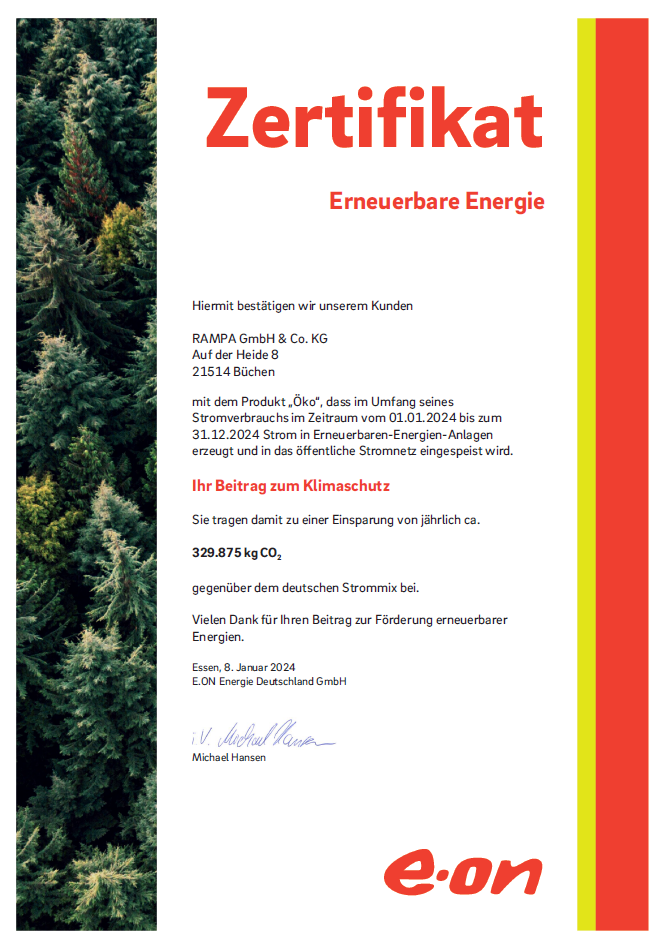

We also focus on sustainability concerning the consumption and use of electricity in our company and make an important contribution to environmental protection: Through the energy supplier E.ON Energie Deutschland GmbH, we have been procuring our electricity requirements exclusively from renewable energy plants since January 1st, 2021. Due to this fact, we contribute to an annual saving of approx. 329,875 kg CO₂ for 2024 compared to the German electricity mix.

Since then, further steps to reduce consumption as well as our own electricity and heat generation have already become reality with our new KfW40 production and office complex. But we also continue to invest in energy-saving measures in our existing buildings, which included, for example, the conversion to LED lighting.

In addition, at the beginning of 2023, we received the certificate of energy savings from Süwag via the implementation of a subsidized energy audit (BA FA) in accordance with DIN EN 16247-1. The European DIN standard defines the characteristic of a qualitative energy audit. It represents an important step towards improving energy efficiency, reducing energy consumption, and benefiting the environment. You can find the certificate here.

Our KfW-40 building

Furthermore, the consolidation of our sites is part of our action roadmap. Our new building was completed in spring 2023. The building is one of the first commercial properties in northern Germany to meet the requirements of the federal subsidy for efficient buildings in non-residential sectors. As one of the few KfW40 commercial buildings in northern Germany, we focus on the use of renewable energy by installing a photovoltaic system on the roof and installing an efficient ventilation and heating system.

RAMPA-bicycles to promote the use of public transport

To encourage our employees to use public transport to get to work, we have made bikes available at Büchen station since May 2022 under the motto “RAMPA makes you mobile!”. To reduce CO₂ emissions, we need the cooperation of the entire RAMPA team. We have created an incentive with the RAMPA bikes to use public transport more often and thereby do something for our environment and our own health. Again, this demonstrates: Our enthusiasm is for the wealth of possibilities. Good idea. Let’s make it!

-

This is what our employees say about the RAMPA-bicycle offer:

“I think it’s great that RAMPA deals with sustainability issues and implements and realises projects from which the employees benefit”.

-

We have proven ourselves again: FOCUS seal for TOP CLIMATE ENGAGEMENT 2024

RAMPA has once again succeeded in having our commitment to climate protection in 2024 awarded the TOP CLIMATE ENGAGEMENT seal by FOCUS. This is the second year in a row that we have received this recognition.

The FOCUS recommendation list includes companies in Germany that are particularly ambitious in their commitment to climate protection. The analysis was based on an in-depth study by FactField, which identified companies that have demonstrated their commitment to climate protection and at the same time are perceived by the public as climate-friendly.

6,700 companies were invited to take part in an online survey following a pre-selection process. In the end, 205 companies from 20 different business sectors received the prestigious FOCUS seal recommendation. We are proud to be one of these award-winning companies. Find out more about the survey process here.

Our passion for environmental protection and sustainability drives us to constantly look for improvements in our operational processes and practices. In 2024, we made significant progress in our efforts and achieved impressive results in the assessment criteria reviewed by FOCUS.

We achieved the highest score in three out of four main categories, reflecting our continuous efforts and investments in environmentally friendly measures. The FOCUS seal for TOP CLIMATE ENVIRONMENT 2024 encourages us to go further and achieve the best results for the environment and our community.

Read here how RAMPA performed within the "Industry and Manufacturing" sector in Germany.

*According to the Greenhouse Gas Protocol