RAMPA inserts for plastic applications – Good idea. Let’s make it!

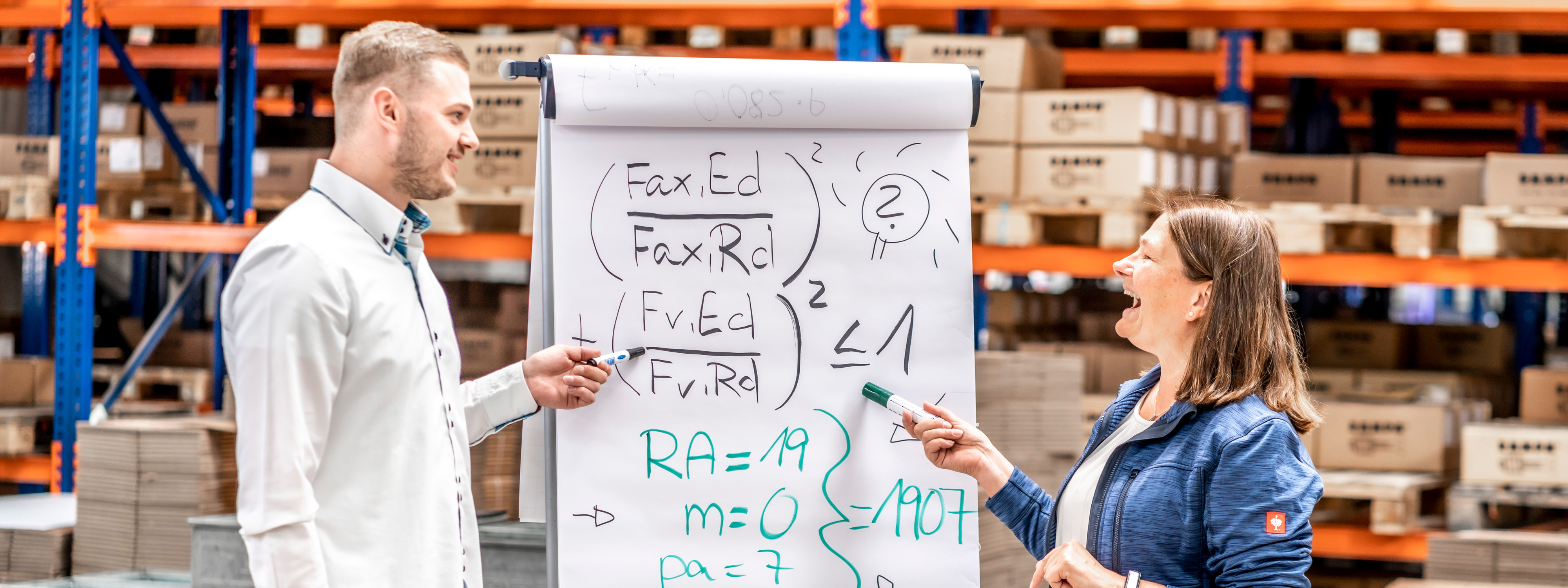

Would you like to discover which RAMPA inserts are suitable for your specific plastics application? We are enthusiastic about the many possibilities - in plastics too. It all started in 1907 with our RAMPA screw-in inserts for wood applications. Since then, we have continuously developed and expanded our range to include threaded inserts for plastics processing and metalworking.

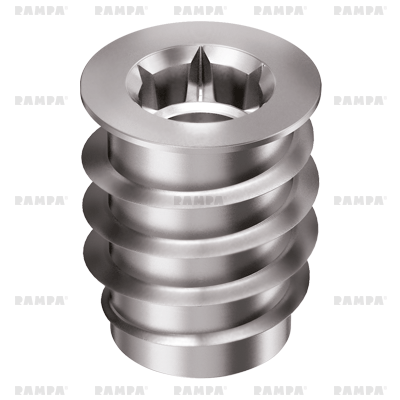

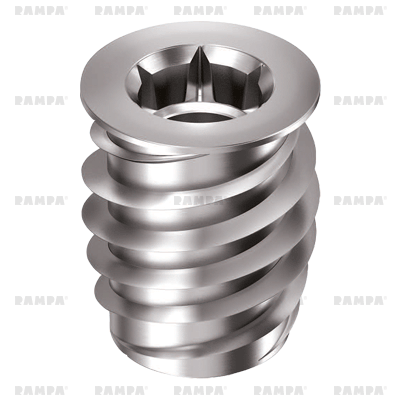

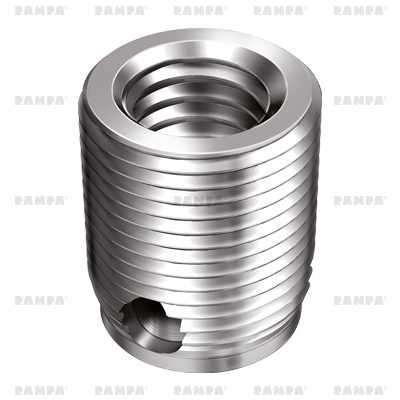

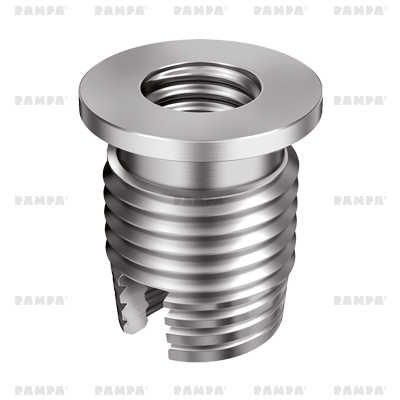

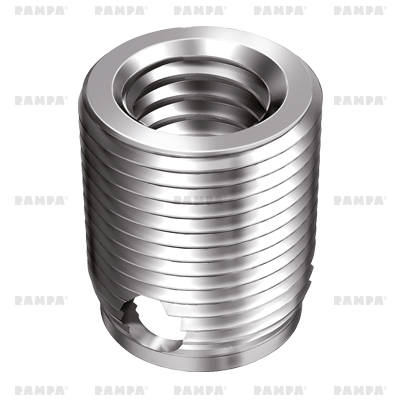

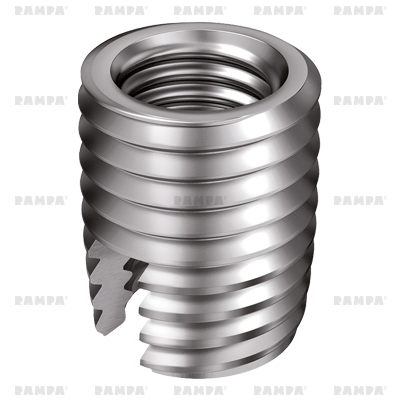

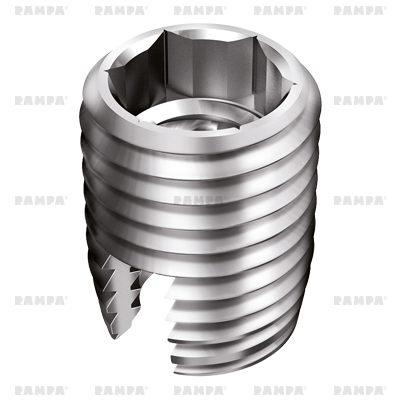

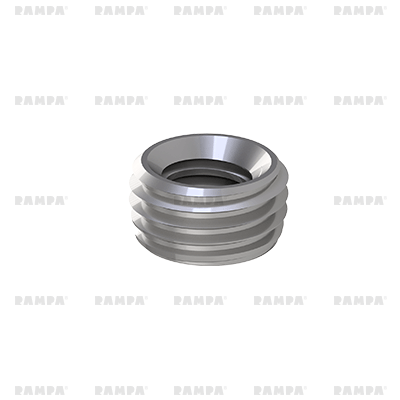

We have made it our business to develop all-round solutions. Our threaded inserts and matching screws are optimally suited for a wide range of materials or alloys. Our self-cutting RAMPA inserts and threaded inserts of the 30 and 330 series, for example, are true all-rounders.

Whether wood, metal, or plastic application: With these connectors you reduce the variety of threaded inserts while maintaining a high level retention holding force, or optimum strengths, in your construction.

Nevertheless, in special cases the standard solution is not suitable. Even then, we know what to do and, with the help of our many years of experience in connection technology , we will find or develop a custom-made solution specifically for your application.

There are countless plastic compositions and even more applications or possible uses for our threaded socket in plastic. Constantly changing requirements, for example with regard to strength, component weight and resistance to certain media, require an individual assessment of the application.

Our self-cutting threaded inserts are suitable for almost all thermoplastics (e.g. PA6G, PE1000, POM C or PTFE) and are sometimes also used in thermosets (e.g. HPL/compact panels). Due to the self-cutting properties, only low pressure is introduced into the material, so that the screw-in cap, for example, does not have to be excessively large. Our 30 and 330 series are also ideal for thermoplastics.

Do direct screw connections in plastic cause difficulties? Instead, rely on our RAMPA inserts with high retention holding force! This is how "strong" our screw-in inserts for plastic are: The RAMPA insert type SKD330 D x L 12 x 15 M6 in the material PA6G carries an average of 1400 kg (pure tensile load).

With our RAMPA inserts, we enable you to make a permanently detachable connection. Forget about stripped threads due to incorrect application of the screw. And forget about possible "seizing" of the thread during repetitive disassembly. These problems are a thing of the past with our threaded inserts. Our threaded inserts also provide a clear cut-off point for screw assembly with torque tools. Good idea. Let’s make it!

Advantages of using RAMPA inserts in plastic applications at a glance:

- The external thread enables low-stress processing and ensures process-reliable and reproducible screw-in conditions.

- Wide range of applications: Appropriate screw-in inserts and the associated screwing-in tools for a wide range of plastics - No pre-cutting required in the pilot hole

- Different designs of threaded inserts for plastics available, including with collar or, for example, with chip spaces. This eliminates the need for additional cleaning of the screw-in area.

Fields of application of our RAMPA inserts in plastic:

Plastics are used in a wide variety of forms and compositions. In the following other areas, for example, threaded inserts from RAMPA can be found:

- General mechanical engineering

- Electrical appliances

- Household appliances

- Vehicle engineering

- Medical devices

- And many more!

For even more details about the many possibilities for using our threaded inserts and matching accessories in plastic applications, take a look at our inspiration section or our reference projects! In the RAMPA shop you can conveniently order the required threaded inserts, inserts, screws and more online.

If your specific connection challenge is not catered for, please contact us! The application possibilities of our RAMPA inserts in plastic are almost inexhaustible. And if our wide range of standard products does not include what you are looking for, we will work with you to develop a custom-made solution for your customized project. Feel free to contact us for a consultation! Good idea. Let’s make it!